TCLAD

Pioneering Thermal Innovation for the World’s Most Demanding Electronics

About tclad

Leaders in Advanced Thermal Management for High-Power Electronics

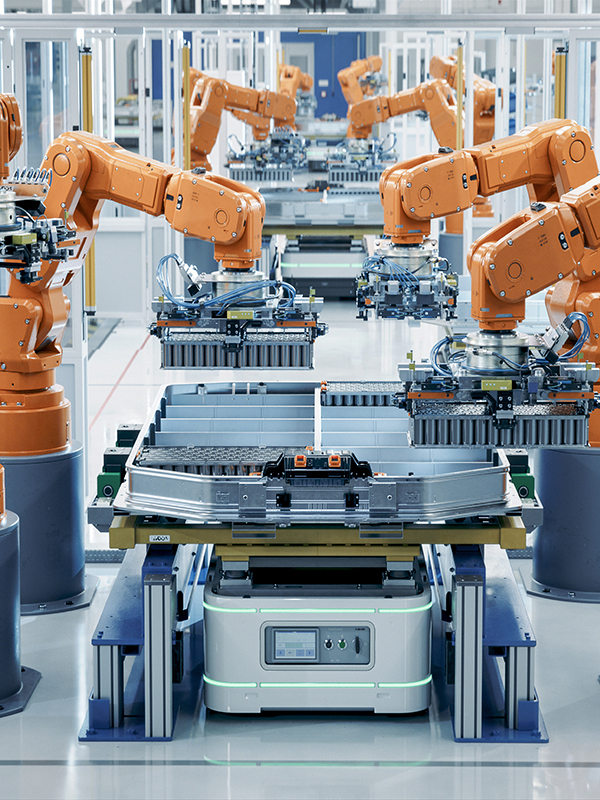

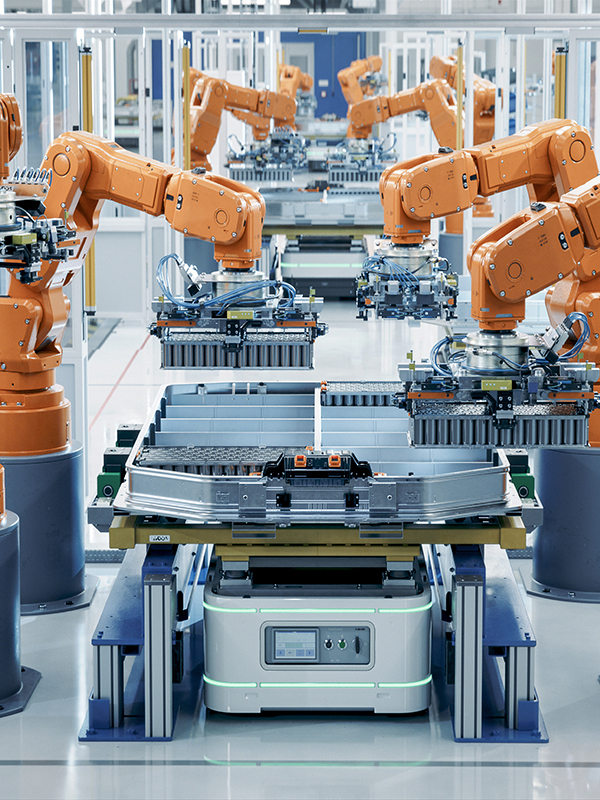

TCLAD specializes in advanced thermal management solutions engineered to meet the stringent performance demands of high-power and high-reliability electronic systems. Our core technologies include Thermally Conductive Printed Circuit Boards (PCBs/PWBs) and Thermal Interface Materials, all produced within our vertically integrated manufacturing facility in Prescott, Wisconsin.

Designed to efficiently dissipate heat and maintain electrical integrity, TCLAD products enable higher power density, improved system efficiency, and enhanced durability. Our materials and processes are optimized to minimize thermal resistance, reduce warpage, and ensure consistent reliability under harsh operating conditions.

TCLAD supports a wide range of industries, including aerospace and defense, automotive, and industrial automation, providing engineering collaboration, rapid prototyping, and custom design support to solve complex thermal challenges from concept through production.

Products

Insulated Metal Substrate

Thermal Interface Materials (TIMs)

Overcurrent Protection (OCP)

Thermal Clad Dielectric Materials

Immersion Cooling Fluids

Board Level Solutions

Surface Mount Thermal Bridge

Quality & Safety Certifications

At TCLAD, we conduct rigorous electrical and thermal testing in our state-of-the-art laboratories and undergo regular audits to ensure full compliance with the highest quality and safety standards.