SNA Electronics

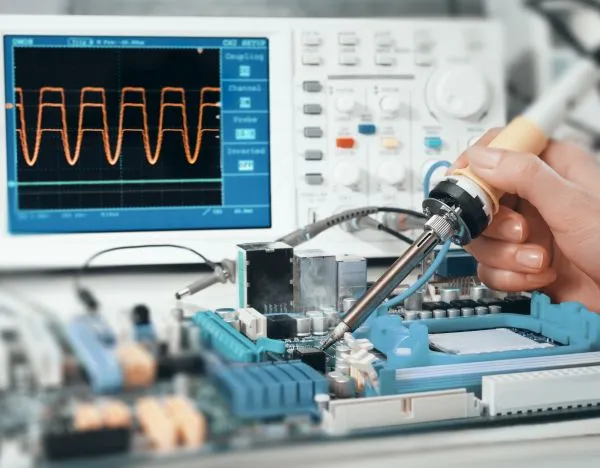

SNA Electronics provides “Total Solutions” in Electronics Manufacturing. Committed to bringing quality electronic manufacturing services to leading original equipment manufacturers.

About SNA Electronics

SNA Electronics provides “Total Solutions” in Electronics Manufacturing.

SNA Electronics was founded in 1996 to bring quality electronic manufacturing services (EMS) to leading original equipment manufacturers (OEMs) such as Networking, Medical Instruments, Aerospace and Defense products, Telecommunication, Wireless Devices, RF Applications and Consumer Electronics.

At SNA Electronics, quality is the overall commitment to excellence for customers. As a superior leader of contract manufacturing, our objective is to obtain highly qualified employees, research new manufacturing processes and technologies, and provide the highest level of quality products and services to customers. In order to achieve this level of excellence, SNA Electronics focuses on continuous improvement in all of our resources and systems.

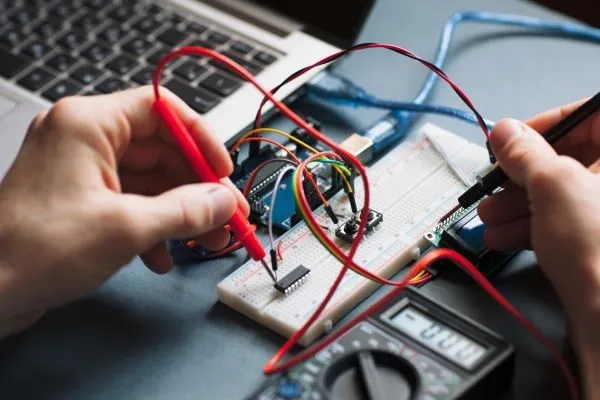

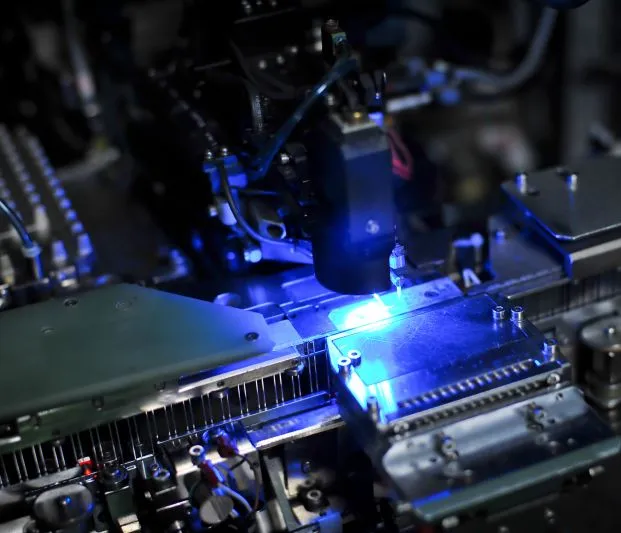

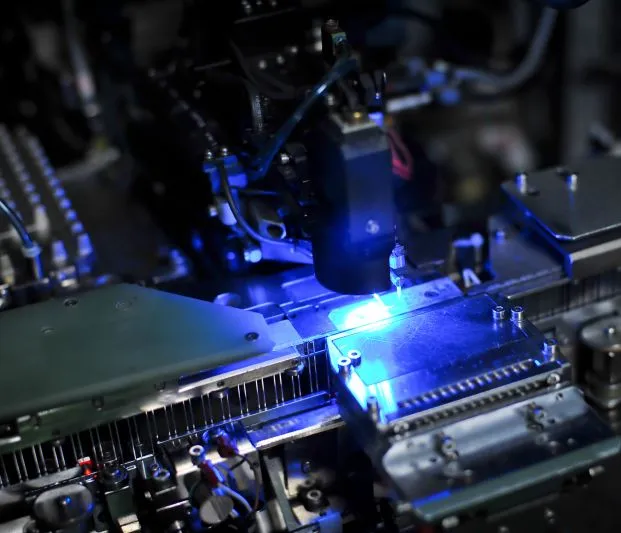

Manufacturing services:

- PCBA (Printed Circuit Board Assembly): The service includes the technology of SMT (Surface Mount Technology), PTH (Pin Thru Hole) and mixed SMT/PTH with BGA (Ball-Grid-Array), LGA (Land-Grid-Array), CSP (Chip Scale Package), Fine Pitch and double sided.

- Cable & Wire Harness

- Box, Chassis & System Assembly: The service includes the configuration & final integration.

- Final Package

- Quick-Turn Prototype: High Complexity Prototype Assemblies.

- New Product Introduction (NPI)

- High Mix, Low Volume Manufacturing

- PCB Manufacturing Ability Review

- Total Material Control: Consignment and Turnkey Project with sophisticated MRP system

- X-Ray Inspection System and Automated Optical Inspection (AOI)

- BGA Rework

- ROHS (Restriction of Use of Hazardous Substances) Process: Lead (Pb) Free Assembly

Engineering services:

- Manufacturing Ability Review: Design for Manufacturing (DFM) Review

- PCB Design & Components Application Review

- Workmanship Standard Review

- Optimization of Manufacturing Processes and Operations

- Machine Program and Setup

- Process Control with Data & Record Control

- Manufacturing Process Instructions

- Documentation Control with ECN (Engineering Change Notice/Order) and Deviation

- Quality Report for Inspection & Testing

Testing services:

- In-Circuit Test

- Functional Test

- Burn-In Test

- Hi-Pot Test

- Power Supply Test

- System Test: Configuration & Integration Test

- Reliability Test: Elevated Temperature Power Cycling Test, Environment Stress Screening Test

- Warranty/RMA Test

- Testability Review: Design for Testing (DFT) Analysis

- Test Report