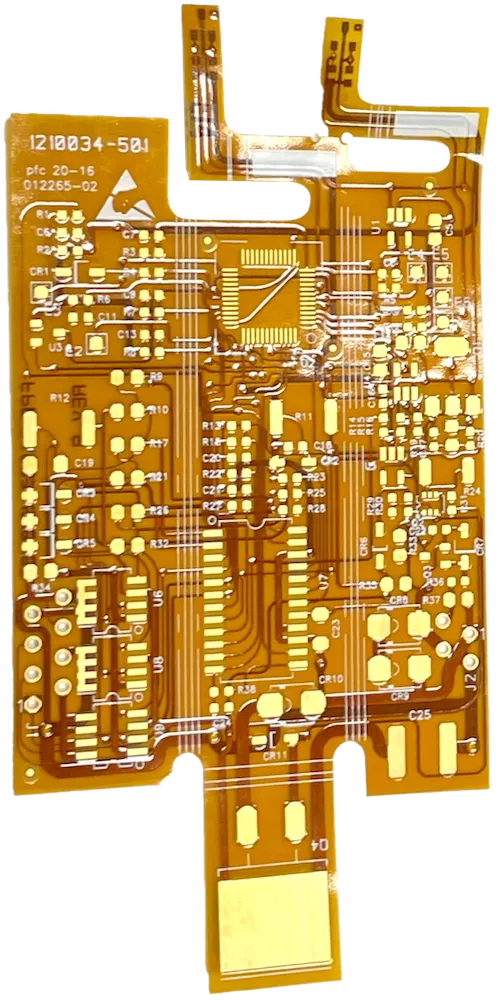

PFC Flexible Circuits

Full turn-key solutions for flexible printed circuits and rigid flex. PFC’s team has extensive design, development, manufacturing, and assembly experience providing high quality flex circuits.

About PFC Flexible Circuits

Pushing the Limits of Possibility!

Since our founding in 1997, PFC has delivered leading flex circuit technology across several markets. Ours extensive engineering experience allows us to work hand-in-hand with our customers to develop cost-effective solutions correctly the first time. Specializing in low to mid volume complex flex circuits, our team provides design, manufacturing, and assembly with advanced capabilities to meet our clients’ most challenging needs.

Products

The mechanical and electrical needs of a project determine the type of flexible circuit used. When selecting a flexible circuit, weigh the advantages of the circuit against the total installed cost, including inspection, interconnection, tooling and testing. PFC experts help guide clients on the best flex circuit to maximize efficiency and minimize costs.

Single sided

Rigid Flex

Double sided

Sculptured Flex

Multi Layer

High Speed Data Links

SERVICES

DESIGN SUPPORT

PFC helps with the design of flex circuits for thinner, lighter, and smaller technology using a special set of requirements unique to flexible circuitry. Understanding how these requirements interact allows them to create flex circuits that balance the electrical and mechanical features into a reliable, cost-effective interconnected solution. They deliver dynamic products that ultimately enable clients to reduce material and labor costs and limit the number of complex connections in a design.

DEVELOPMENT

PFC delivers full turnkey flexible circuit development. Their experienced team evaluates customer processes and products to provide insight on flex circuit efficiency. PFC’s early customer engagement process will develop the best design and engineering solutions.

MSNUFACTURING & ASSEMBLY

PFC provides leading companies with customized flex circuit solutions and unbeatable customer service. Their integrated technologies and processes provide their clients’ a range of advanced flex and rigid flex circuits. Their team’s high level of technical capability supports production and quick-turn manufacturing requirements. With all manufacturing processes under one roof, PFC has the ability to manufacture end-to-end flexible circuits.